As industry converge, Caetano Coatings uses industry expertise to create new value and opportunities for business. We identify and provide complete services while offering the right solutions to increase the availability and productivity of our clients.

Electro-Coat for Automotive & General Industry

Info

- Focus on Automotive parts

- General Industry

- Aluminium and Steel capability

- More than 5 M parts/year

- Paint area per rack:

- 3.100 X 1.700 X 800 mm

- Pre-Treatment with Spraying and Deep Immersion

- Up to 300 kg per rack

Process Flow

- 8 Stages Power Wash with pickling

- (4 spraying + 4 immersion)

- E-Coat with automatic settings programs

- 3 Stages Power Wash UF

- Curing Oven

- 100% Visual Inspection

- Packaging

Powder Coating for Automotive Industry

Info

- Focus on Automotive parts

- Aluminium and Steel capability

- Primer Powder

- Black High Gloss Powder

- Textured and Flat Powder

- Fully automated

- 1 Painting Layer

- More than 4,3 M parts/year

- Paint area per rack:

- 3.100 X 1.700 X 500 mm

Process Flow

- 8 Stages Power Wash

- Dry OvenCooling

- Powder Coating

- Curing Oven

- 100% Visual Inspection

- Packaging

Powder Coating for General Industry

Info

- Focus on High requirement parts

- General Industry

- Several Colors Painting

- Fullyautomated

- 1 Painting Layer

- More than 900.000 m2/year

- Paint area per rack:

- 6.000 X 1.700 X 600 mm

Process Flow

- Assembly Jig’s

- 6 Stages Power Wash

- Dry Oven

- Cooling

- Powder Coating

- Curing Oven

- 100% Visual Inspection

- Packaging

Wet Painting

Info

- Focus on Automotive parts

- General Industry

- Body Color Painting

- Soft-Touch Capability

- Aluminium, Powder primed, Plastic, Steel E-coated

- Cost-effective for low volumes

- Solvent and Waterbourne

- Fully automated

- 6-axis Painting and Flaming Robots

- Nanobell technology

- 3 Painting Layers

- More than 6 M parts/year

- Teach Robot for off-side programing

- Paint areas per rack:

- 1.500 X 300 X 300 mm

- 2.100 X 1.500 X 500 mm

- 2.500 x 1.500 x 500 mm

Process Flow

- 8 or 3 Stages Power Wash

- Blowing Robotized

- Dry Oven

- Ionized Air Blowers

- Flaming Robotized

- Primer Coat Robotized

- Flash Off

- Base Coat Robotized

- Flash Off

- Clear-Coat Robotized

- Curing Oven

- 100% Visual Inspection

- Packaging

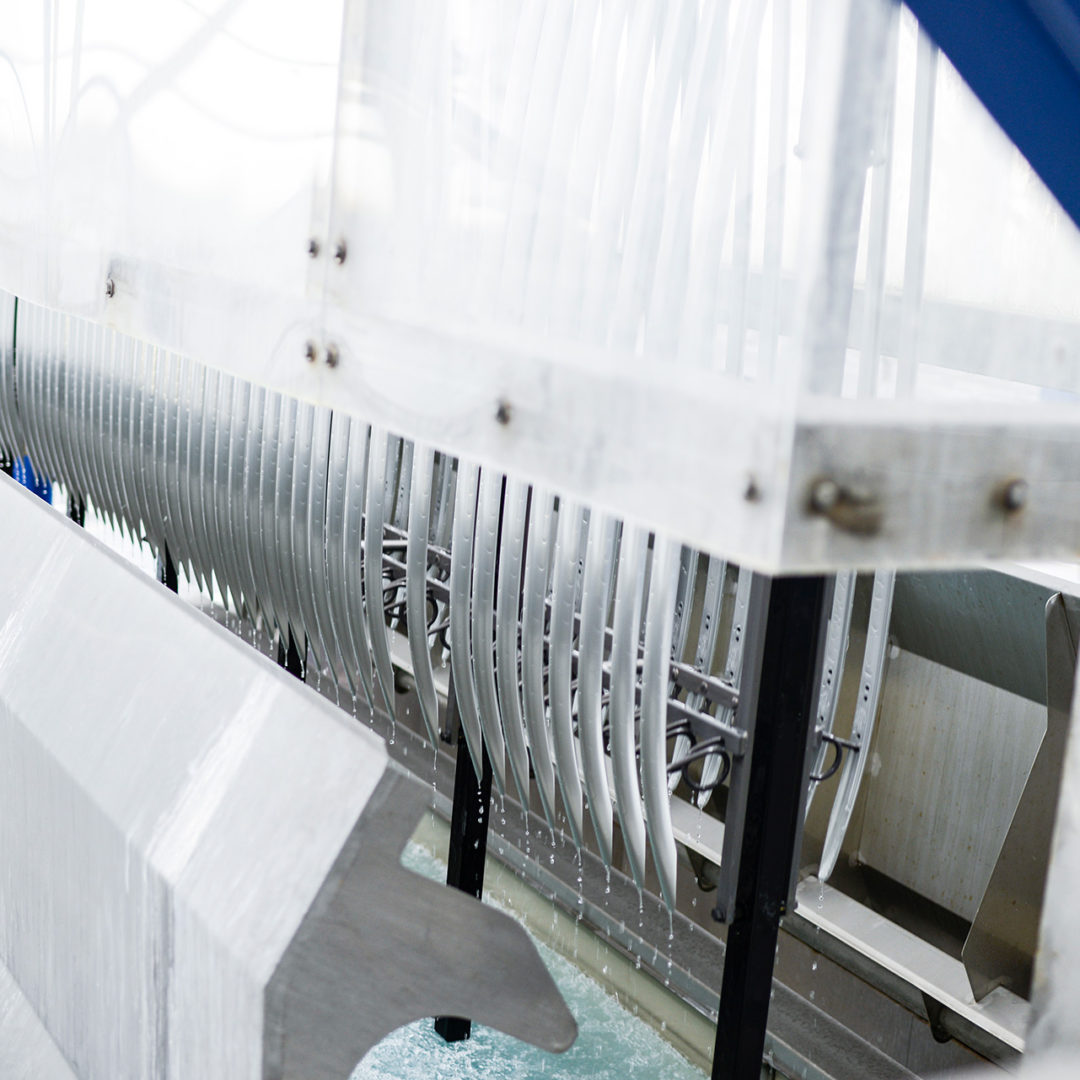

Anodizing

Info

- Focus on Automotive parts

- General Industry

- pH 12,5 and pH 13 resistance

- High Gloss, Satin and Matt surfaces

- 2 Electro-Polishing tanks

- 4 Anodizing tanks

- Black High Gloss capability

- More than 3 M roof rails/year

- Anodizing area per rack:

- 4.000 X 2.500 X 500 mm

Process Flow

- Pre-Degrease

- Degrease

- Electro-Polishing

- Alkaline Desmut

- Acid Desmut

- Anodizing

- Electro-Colouring (black as optional)

- Cold Sealing

- Hot Sealing

- Warm Rinse

- Drying

- 100% Visual Inspection

- Packaging

FSS – Full Service Supplier

Caetano Coatings is a Full-Service Supplier (FSS), providing all project specifications from drawing to delivery of the final product to OEM.

Our customers can choose a broad range of services. Beyond Caetano Coatings core competence, customer needs can be achieved through a strong partnership comprising a capable project management team and a reliable and certified network of sub-suppliers.

FSS means: You provide all necessary project specifications, such as CAD data or drawings, project timing and other project related information. With our suppliers/partners, our project management team is carefully following up all needs and tasks from the beginning of the project until SOP and beyond.